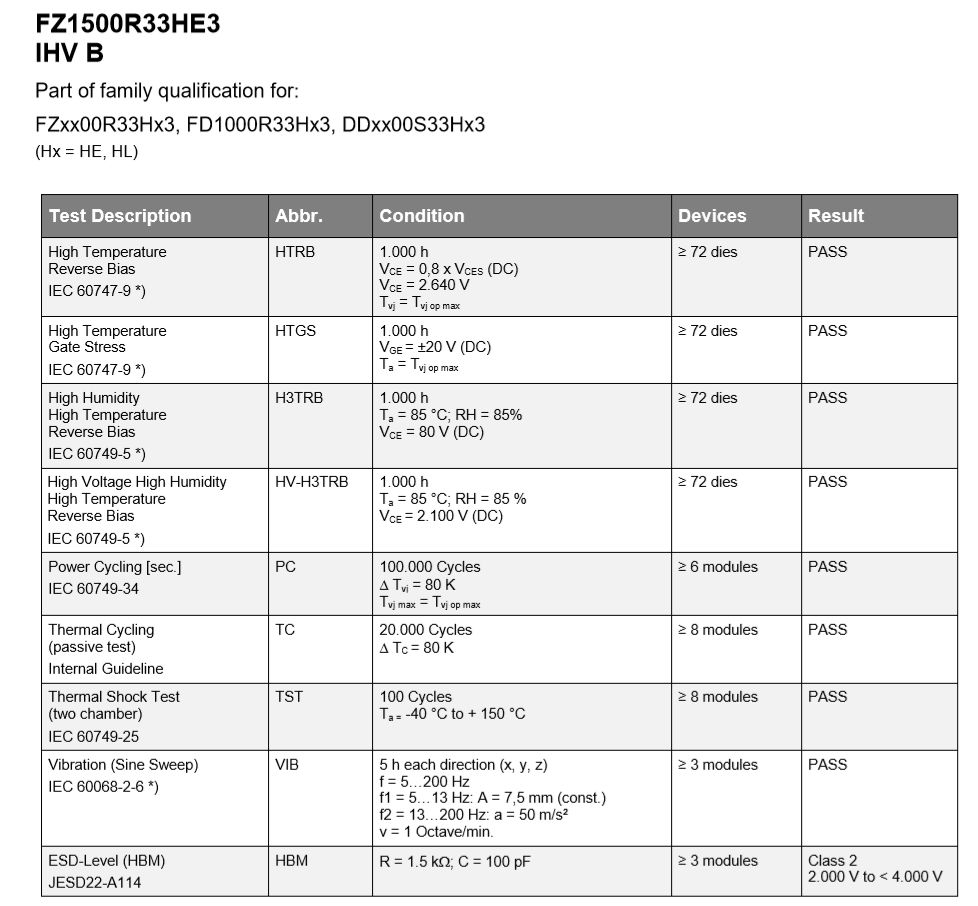

In order to ensure the durability of the product, that is, the service life of the product. IGBT module manufacturers will conduct a series of reliability tests before product finalization to ensure the long-term durability of products. The common test items are shown in the figure below.

This is from an Infineon report on 3300v Product qualification report of ihv-b packaging product series Report。 The test items in this report, except ESD electrostatic test, are related to the life of IGBT module. Life related testing can be divided into two parts, one is the assessment of the life of the chip itself, and the other is the assessment of mechanical connection. The assessment of the life of the chip itself includes the following contents:

HTRB, high temperature and high pressure reverse bias test, test the reliability of IGBT chip under high pressure.

Htgb, high temperature gate stress test, test the withstand voltage reliability of IGBT chip gate.

H3trb, high temperature and high humidity reverse bias test, to test the reliability of IGBT chip in high humidity environment.

Hv-h3trb, high pressure, high temperature and high humidity reverse bias test, which is a more rigorous version of h3trb, because the essence of high humidity is a kind of corrosion to the passivation layer of the chip, and high pressure will accelerate this corrosion.

The above items are mainly to evaluate the durability of the chip. Under these test conditions, as long as the time is long enough, the chip will be broken.

For IGBT module, the outside of the module is the shell and metal terminal. There are not only chips, binding wires, insulating ceramic substrate and welding layer inside, which are collectively referred to as mechanical connection. How to evaluate the durability of these mechanical connections? This is power cycling, thermal cycling, thermal shock, and vibration testing.

Current situation of IGBT module life evaluation

Life evaluation method of IGBT module that can be implemented under the current technical level -- related life of metal, welding and mechanical fatigue

At present, it is recognized that the algorithm that can best reflect the actual fatigue life of metal - rain flow counting method

At present, it is recognized as the most effective experimental basis for IGBT module life evaluation - power and thermal cycle test capability

Since there is no industry recognized calculation method for the reliability and anti vibration ability of the chip to connect the accelerated test results with the actual service life, and there is a more accurate method to convert the actual service life of the power and thermal cycle. For most of the current common packaging processes, the power and thermal cycle are still the short board in the actual service life, so it is necessary to study the power cycle, To calculate more accurate actual life capacity.

What is power cycle?

Power cycle Cycling, as its name implies, is to make the chip intermittently flow current to generate gap heating power, so as to make the chip temperature fluctuate. Because the heat source is the heat generated by the chip itself, it is generally called active heating. The cycle of power cycle is generally 3 ~ 5 seconds& nbsp; < br/>

The damage mechanism of power cycle to IGBT module is mainly caused by the difference between the thermal expansion coefficient of copper binding line and that of aluminum layer on the chip surface, and the difference between the thermal expansion coefficient of chip and DBC board. The main damage results are the falling off and fracture of the binding line and the separation of the chip welding layer。

How to conduct power and thermal cycle test

Iec60749-34 describes the circuit connection method of reliability experiment, while iec60747-9 describes the test method of IGBT parameters and the criterion of failure standard. For the power cycle, if the on voltage drop of the device exceeds 5% of the initial value or the thermal resistance exceeds 20% of the initial value, it is determined as failure.

However, the method of power cycle test loading in the industry is not uniform. Impact of test control strategy on power cycle In this article, lifetime discusses the four load method:

Constant on and off time: keep constant on time, off time and on current during the test< br/>

Constant shell temperature Tc fluctuation: gradually turn off the conduction time and maintain constant shell temperature fluctuation & nbsp;

Constant power PV: during the test, the constant power is always maintained by reducing the conduction current

Constant junction temperature TJ fluctuation: during the test, reduce the conduction time to maintain constant junction temperature fluctuation

The following figure shows the test results. It can be seen that the test results of four test methods for one IGBT module are very different. With constant on and off time, the device fails at 35000 cycles. The second method of constant shell temperature is 45000 The third constant power method will fail in less than 70000 cycles, while the fourth constant junction temperature method can reach more than 95000 cycles. This result is also easy to understand. We know that the number of power cycles is closely related to the fluctuation of junction temperature. With the progress of power cycle, the conduction voltage drop and thermal resistance of the tested device are bound to rise. If the conduction time and conduction current are constant, the junction temperature of the device in the later stage of aging will be higher than that in the early stage of testing, and the number of power cycles that the device can withstand will be less than that of the constant junction temperature method.

The following is the research results of keminiz University. They listed six test methods. The constant power method is divided into two methods by adjusting the on current and gate voltage, while the constant junction temperature method is divided into three methods by adjusting the on current, gate voltage and on time. Among them, the most rigorous constant pulse method is more than 50% different from the most relaxed method of reducing conduction time and maintaining constant junction temperature.

This is a huge gap, so when judging the life of a power device PC, it depends not only on the cycle value of the power cycle, but also on the test method. The power cycle curve of Infineon module is tested according to the most stringent conditions, that is, the method of constant conduction time and conduction current, so as to ensure that the product has the highest level of reliability.

The comparison of tested samples is limited. How can the life results under limited samples be scientifically counted as a reliable life value? That's another interesting topic. Interested students can look at this paper.

We'll talk next time.

皖公网安备 34020302000234号Sitemap

皖公网安备 34020302000234号Sitemap